Stainless Steel Applications

Performance

Each item you purchase should be made of material that can perform its job completely and consistently. This requires the consideration of several properties, some of which are explained below.

Hardness vs. Flexibility

Often, optimum performance requires a perfect balance between hardness and flexibility/formability. For example, a butter knife is made to be flexible; in addition to making it the perfect tool for buttering bread, this flexibility allows the knife to “give” a little so it won’t break as easily under pressure. On the other hand, if a knife is too flexible it will easily bend out of shape and have to be replaced often. The same concept applies for items where denting is a concern, such as steam table pans and buffet line cabinets.

Often, optimum performance requires a perfect balance between hardness and flexibility/formability. For example, a butter knife is made to be flexible; in addition to making it the perfect tool for buttering bread, this flexibility allows the knife to “give” a little so it won’t break as easily under pressure. On the other hand, if a knife is too flexible it will easily bend out of shape and have to be replaced often. The same concept applies for items where denting is a concern, such as steam table pans and buffet line cabinets.

The hardness of stainless steel is determined in part by the amount of carbon added to the stainless steel formula. A high percentage of carbon adds strength, but too much carbon can make steel brittle and difficult to form. As a reference, 304 stainless steel contains about 0.04% carbon.

As previously mentioned, the addition of nickel also makes steel softer and easier to form. One way to increase the hardness of steel is to decrease the percentage of nickel. The standard baseline for foodservice equipment has been the 8% nickel found in 304 grade, but manufacturers are finding that the 6% nickel in 301 still allows enough malleability to form items such as cookware. Manufacturers are also experimenting with the partial substitution of manganese, which has similar properties to nickel. In any case, if manufacturers try to cut back too far on their use of nickel without somehow substituting for it, their steel may be pushed to its physical limits during production, resulting in products that are more likely to crack while in use.

Durability

If equipment fails to get daily jobs done without scratching, bending, or breaking, it obviously is not going to rate well over the long term either. On the other hand, just because a piece of equipment can hold up through immediate jobs, that doesn’t guarantee it will last. As we have already learned, if the essential elements chromium and nickel are lower than they should be for a given application, bending, cracking, scratching, corrosion, and staining can occur. These can happen in such small increments that you don’t notice it on a daily level, but you are guaranteed to see the consequences over time.

The Test of Time

Automatic dishwashers and salty and acidic foods like mustard and sauerkraut can be hard on stainless steel. For this reason, foodservice equipment manufacturers must pay special attention to the corrosion-resistance properties of their stainless steel, especially in products like cookware and steam table pans that will have direct contact with food.

Regular carbon steel is a combination of only two elements, iron and carbon. This type of steel is hard and strong, but also susceptible to corrosion. Add chromium to the mix, and steel becomes “stainless,” which means that it becomes resistant to corrosion and staining (it should be noted that because it is made mostly of iron, no steel is 100% resistant to corrosion). To be called stainless, steel must have a minimum of 11% chromium. 304 stainless steel has 18% chromium.

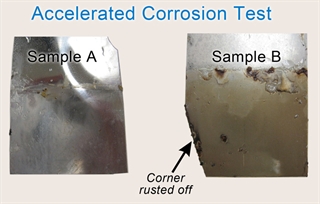

Samples were suspended in a 170 degree F, 3:1 ratio water-bleach mixture for eight hours. Sample B contains only 2% less each of nickel and chromium than Sample A, and the drop in corrosion resistance is substantial.

Samples were suspended in a 170 degree F, 3:1 ratio water-bleach mixture for eight hours. Sample B contains only 2% less each of nickel and chromium than Sample A, and the drop in corrosion resistance is substantial.

But once again, nickel also plays a role. Chromium protects stainless steel by forming a protective layer over its surface (called a passivation layer). But when this layer gets scratched, the steel underneath can be exposed to corrosion and staining. Nickel not only has corrosion-resistant properties of its own, but it also helps re-form the chromium passivation layer more quickly if the surface of the steel gets scratched. This is essential in, for example, a steam table pan that may regularly be exposed to corrosive foods such as tomatoes, mustard, or sauerkraut. While Pan B (on the right) may have had a smaller purchase price, it will need to be replaced far quicker than a pan with the more appropriate amount of chromium. This is not to mention its lack of NSF certification and possible dangers it presents to your customers.

Aesthetics

Stainless steel has a broad variety of uses, from decorative to workhorse, from back of the house to front of the house. Generally, mirror-finished stainless steel will require a higher amount of nickel. Of course, there are a number of factors that contribute to the quality of a finish, but if the mirror look is what you want, try to do a side-by-side comparison of the products you are considering and determine if their looks “reflect” the amount of nickel they have.

Again, you should also consider the amount of chromium in the steel. The product you are looking at may have a beautiful finish when it is new on the shelf, but if its chromium content is too low, the mirror finish may quickly be replaced by a layer of corrosion, pitting, and/or stains.