Benefits of an Induction Dry Well Drop-in

Running an effective and efficient foodservice operation requires precision. And that exactness isn’t limited to ordering the proper amount of food or finding the perfect balance of ingredients.

It also includes serving food at a specific temperature so that it can be experienced and enjoyed as intended.

Being anything less than exact when it comes to this integral step can result in wasted time, food and money. Or, even worse, a poor customer experience.

Utilizing Modular Induction Dry Well Drop-Ins from Vollrath in your serving setup can help avoid that unfortunate situation.

Steam has outstayed its welcome

Traditional steam wells have been around for years. But as the industry has advanced, the shortcomings of this dated heating method have become clearer. Steam has outstayed its welcome.

Heating via steam is, by nature, less than efficient. It is an indirect heat source. This inherent inefficiency leaves operators at the mercy of several variables:

- Steam lacks responsiveness. In order adjust the temperature of the food, the operator must first adjust the temperature of the heater which, in turn, changes the temperature of the water. This chain of events can take a considerable amount of time, time that is seldom available in the middle of a rush.

- The use of water means filling wells, maintaining water levels and draining wells, often more than once a day. This equals even more time and money. And missing any of these chores could result in poor food quality or even damage to equipment.

- As pans age, they can leave gaps for steam to escape. This means more energy is necessary to create additional steam to heat pans over time.

Each of these scenarios can be the difference between serving up a delectable dish and throwing away half a pan of burned food at the end of a service.

A smarter way to serve

In recent years, heating technology has grown with the industry. The dawn of induction has changed the game.

Vollrath continues to be the leader in induction technology with the debut of its induction dry well drop-ins.

Induction is a direct heat source, making it 2.9 times more efficient than steam.

The key concept of induction is that heat is generated by the pan itself. The induction unit achieves this by creating movement in the molecules of the induction-ready pan. Induction turns the pan itself into the heat source transferring the heat straight to the pan and its contents.

This offers several advantages:

- The direct heat of induction allows for maximum responsiveness. Adjustable controls allow precise temperature setting or choice of 3 power levels in order to maintain the

freshness and quality of food. Two induction zones per well equal even more control. - Induction eliminates the need for water, steam and drains. Thus avoiding the hassle, time and money that comes with needing to fill, maintain and drain wells.

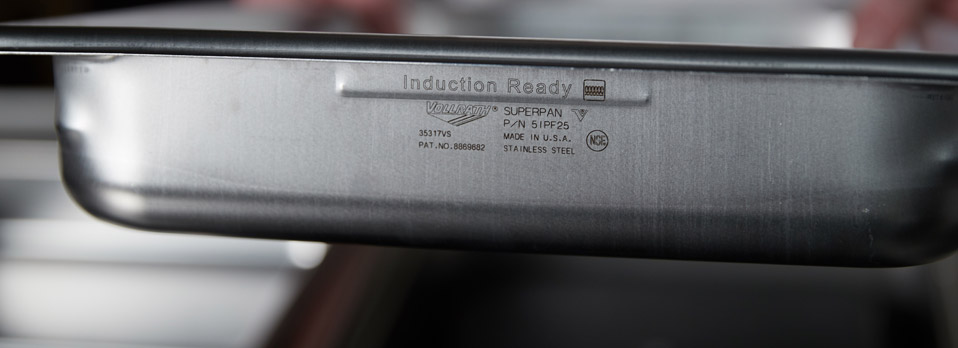

- Vollrath induction-ready pans are specially designed to optimize compatibility and warming performance. This pan becomes the heat source, meaning more efficiency and added responsiveness.

When it comes to running a top-notch foodservice program, there is no substitute for being exact.

Countless hours go into planning, prepping and preparing each meal. Add the finishing touch by choosing a drop-in unit that provides unmatched precision and control.